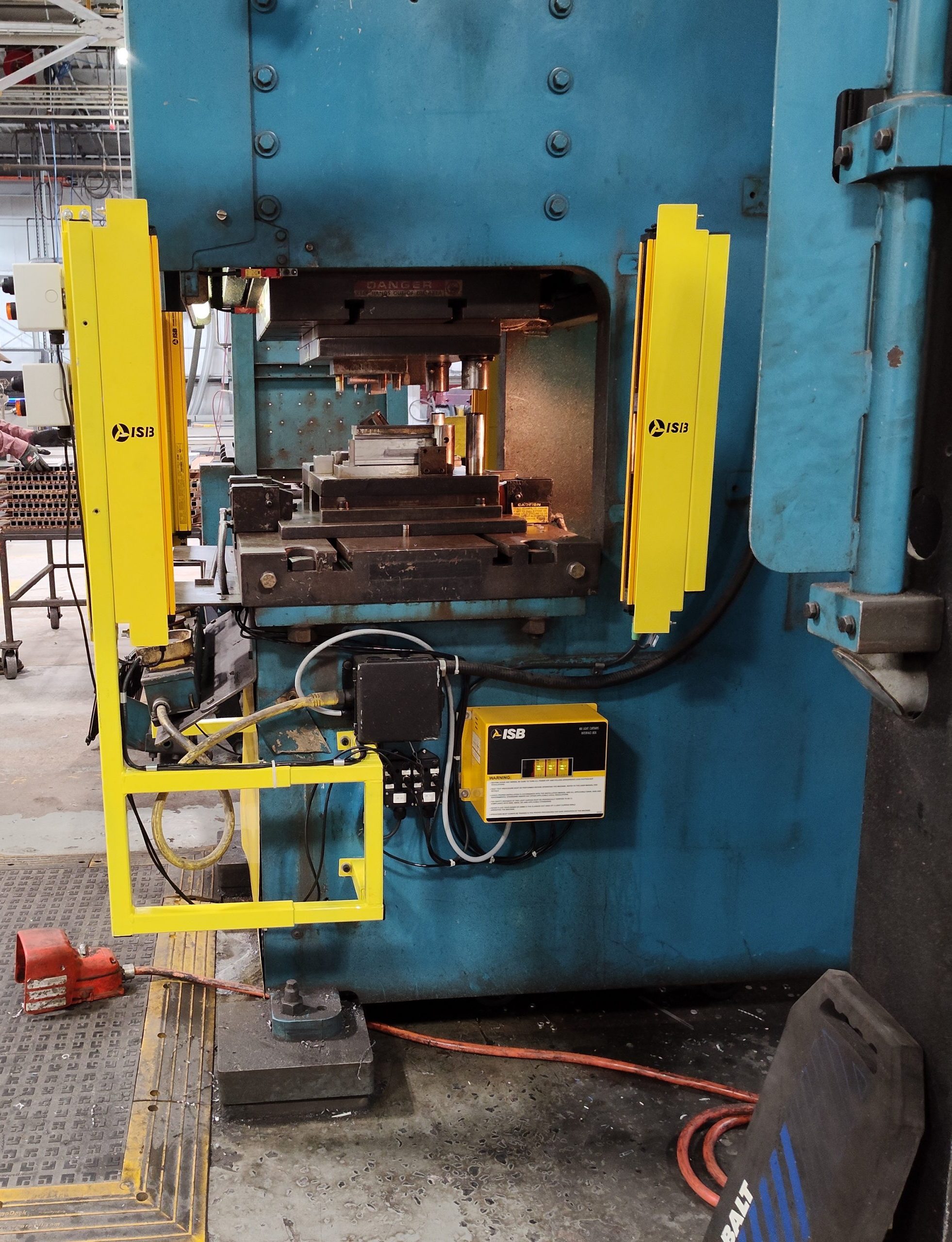

Hydraulic Press being fed from three different sides creates unique challenges for providing operator safety

We recently completed installation of 3 sets of ISB MX4214-600 Safety Light Curtain Systems on a Cincinnati Hydraulic Press at a plant in Pennsylvania.

When we first reviewed this application, the press was already being safeguarded by a competitive light curtain protecting the front and contained adjustable hair pin guards across the left and right sides. The existing safety light had several inches of its protective zone permanently blanked out. With the large hole blanked out in the center of the light curtain and the hair pin guards pushed up and out of the way on both ends, it was clear that this machine’s safety system required much more attention.

The challenges for this application were complicated because all the parts being fabricated were large enough that they passed through the safety light curtain while being fabricated and were being held by the operator. Each part also has a different profile passing through the safety light curtain. To make matters even more complicated, parts were being fed not only through the front, but many were also fed from either the left or right sides of the press and some parts actually penetrated both the right and left side of the press at the same time.

The initial thought was to install one set of safety lights and use 2 mirrors to safeguard all 3 sides. The problem with that approach is that since all the parts have varying sizes of side profile and they penetrate through the safety light curtain while being stamped, this requires a small section of the safety light blanked out to accommodate the part profile. When using mirrors, this blanked out section will provide an unprotected access point on all 3 sides of the press. The risk associated with using mirrors was not acceptable.

The decision was made to install 3 separate ISB MX4214-600 Safety Light Curtains. Each light curtain can be easily blanked out using our portable teach tool. For the convenience of the operators, 3 teach tools were installed. Each teach tool contains a supervisory level key switch and a teach push button for quick and easy beam blank out that allows for fabrication of parts on this type of machine with minimal impact on productivity while providing for a completely safe operation.

ISB’s MX Series Safety light curtains are CE certified by TUV for Type 4 Functional Safety. All wiring boxes are UL listed.

To learn more about the ISB Safety Light Curtains and custom fabricated mounting brackets, please see our Product Brochure.

This system was sold by ISB’s Distributor, Mid Atlantic Machinery. Harrisburg, Pennsylvania. (717) 541-1633

Integration was provided by IM Services, 267-718-7349

Dan@im-services.net, Hatboro, Pennsylvania,

Don’t hesitate to contact us if we can help safeguard your machines. As always, your comments are welcome.

Tony Caruso

Vice President of Sales & Marketing

(Cell) 203 331-3938

Website; www.isblite.com

E-mail; tonyc@isblite.com